Building back cheaper and stronger

One of the lessons not learnt from the earthquake four years ago is the possibility to re-use and up-cycle bricks, metal and timber for reconstruction instead of buying expensive imported material. But it is still not too late.

Traditionally, Nepalis have reused building material for temples, or homes, salvaging and recycling them after every earthquake in the past. Nearly 700,000 houses went down in the 2015 quakes, leaving a huge amount of stone, bricks, useful mud mortar, timber and roof tiles.

In the immediate aftermath of the earthquake on 25 April 2015, survivors quickly built temporary shelters made of bamboo, tarpaulins, planks, corrugated steel sheets and anything else available. Relief agencies supplied corrugated steel sheets, some of which were barely 0.2mm thick and could be bent into semi-circles to make shelters.

Read also:

Lessons Unlearnt, Editorial

Nepal's traditional seismic resistant designs, Sheilin Teo

Tall order, Sewa Bhattarai and Prakriti Kandel

Soon, the temperature in the low valleys rose to 36oC, and the space under the metal became ovens. Temporary schools also overheated, and there were reports of children dehydrating and fainting. Once the monsoon came, the sound of rain on the tin roofs made teaching impossible. Strong winds tore the paper-thin steel sheets loose, turning them into flying guillotines.

Poor families had no other option than to stay in their temporary makeshift houses, turning a large part of Central Nepal into slums. These were not homes.

Our Sustainable Mountain Architecture (SMA) team came up with an alternative design for transitional homes, made from salvaged material and locally grown bamboo or thatch. The base of the single-storey house is a thick, heavy stone wall; the main structure re-uses timber columns, beams and rafters of the family house that came down.

The top part of the walls and the roof are made of lighter material, the horizontal timber tie beams had new metal wires to act as stabilising cross-bracing so they were stronger. Salvaged planks or bamboo, and the compulsory involvement of family members in the building process guaranteed ownership of the transitional homes built for only Rs40,000 each.

Read also:

Shaking up the health sector, Sewa Bhattarai

Quake was a learning experience for Nepal’s schools, Prakriti Kandel

However, after relief money was allocated for the removal of material from ruined houses excellent raw material that could have been used for construction were taken away. Once the government got its act together, it dictated the usage of concrete.

Heaps of local building material was wasted, while salvaged timber started to rot in the rain. Families who could afford it started building reinforced concrete houses. This has been a boom time for the cement and rebar industry. Brick infill walls were made in concrete structures, providing business to polluting brick kilns baking Kathmandu’s fertile topsoil. All this new building material had to be transported by trucks spewing black soot.

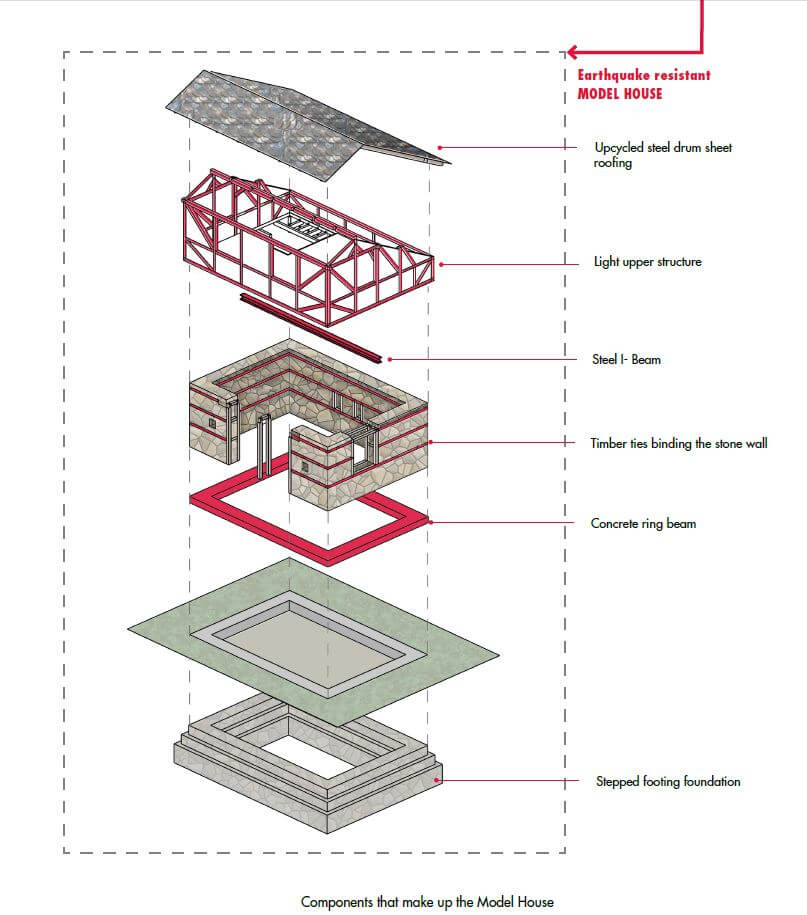

A more permanent design by the SMA team used salvaged material from a collapsed building to make a two-storey model house at the ICIMOD Knowledge Park in Godavari, to demonstrate quake-resistance design for rural Nepal.

Read also:

Nepal is being loved to death, Anil Chitrakar

Nirmala Pariyar's 2nd life, Ramu Sapkota

For retaining warmth in winter, the house — at 1,500m — uses a south-facing asymmetrical saddle roof for passive solar energy gain. While most buildings in Nepal are now using thin, 0.25mm corrugated steel sheet for the roof, we looked for a more robust solution, re-using bottoms of scrap tar drums 60cm in diameter and 1.2mm thick. The completed house rests on a concrete ring beam, the only place where cement is used.

The upper floor is lightweight with timber structure and double wattle and daub walls. These jut out slightly from the lower stone wall with timber tie reinforcements. The largest upper floor span of 6m is made by one steel I-beam, to conserve trees.

Sapana Shakya and Aman Raj Khatakho are architects with Sustainable Mountain Architecture, a Nepali non-profit founded by Anne Feenstra, a Laureate of the Global Award for Sustainable Architecture 2012 (Paris) to promote innovative pro-people, pro-ecology, pro-local building techniques.

BEST USE IS REUSE

Post-earthquake most buildings tend to use reinforced concrete because of the misconception that houses built with traditional techniques and materials will not be strong.

However, with innovation and the right design, the non-profit Sustainable Mountain Architecture has built this model house that uses local material and style to build durable and eco-friendly homes.

This model house is easily replicable, uses local labour and technology, and salvaged material.

The windows and doors of the model house face south. The southern wall is taller, which means the house gets plenty of sun in winter. The passive solar energy that enters the house is trapped in the walls. Double glazing on windows prevents heat from escaping.